MOBILE DRESSING SPINDLE KREBSDRESS

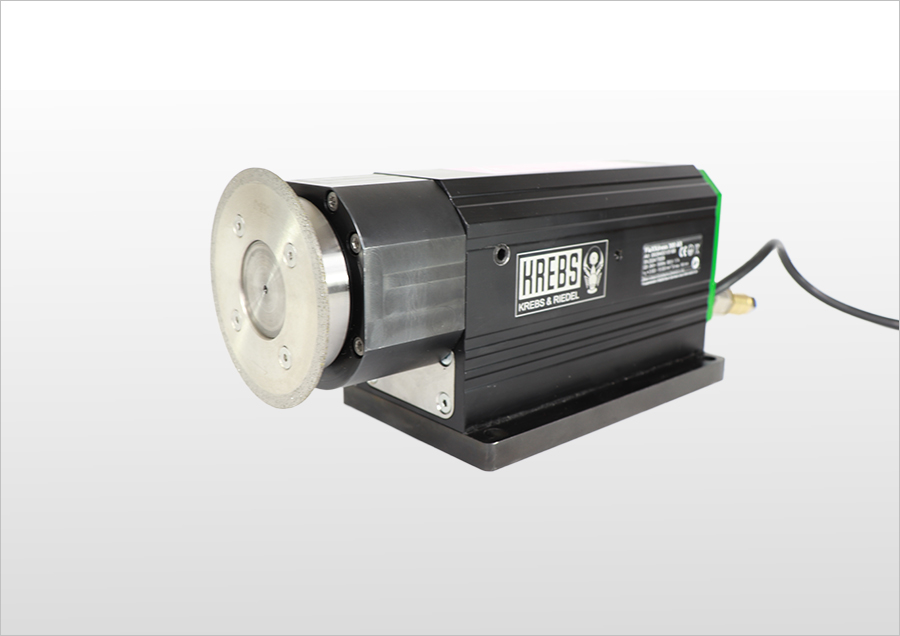

KREBSDRESS is a mobile dressing system that can be easily used on grinding machines without rotating dressing technology. This mobile dressing spindle allows for the dressing and conditioning of vitrified bonded CBN and diamond grinding wheels. The mobile dressing spindle is equipped with a mounting plate for quick and easy installation. It offers optimal adaptation to each grinding application through selectable right or left rotation and variable speed settings.

A fixed dressing system is not always desirable. Universally usable and "handy" systems are a better option for many users, especially smaller companies. For this reason, we have developed the perfect solution: KREBSDRESS is a mobile dressing spindle system that can be easily used on any machines without rotating dressing technology. It can also be integrated into new machine systems.

The mobile dressing spindle offers optimal adaptation possibilities for each dressing situation. These include a wide speed range, actual speed detection with readjustment, the option to select right or left rotation, and the easily integrable control system. To achieve the required workpiece quality, the mobile dressing spindle ensures very high rotational accuracy and stiffness through a sophisticated design and high precision, maintenance-free bearings made in Germany.

The Dressing Spindle - The Heart of the System

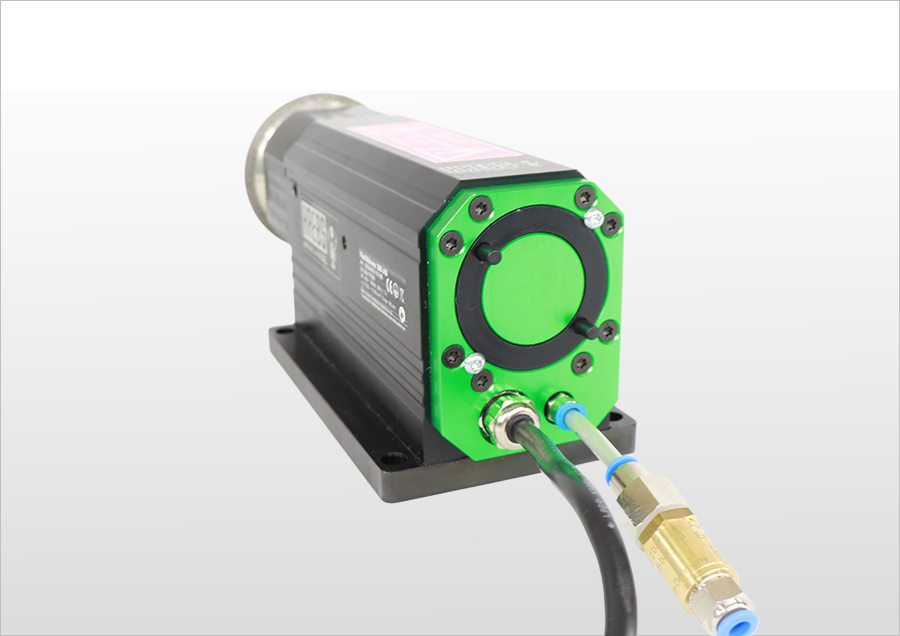

The dressing spindle is the most important component in the dressing system. It is approximately the size of a standard long letter envelope, making it flexible and universally usable. To ensure precision and longevity, the spindle is supplied with sealing air that prevents dirt and moisture from entering the motor and precision spindle bearings, and also cools the motor. Important: Operate the mobile dressing spindle only with connected sealing air! The sealing air hose is not included. The mobile dressing spindle is not designed for continuous operation.

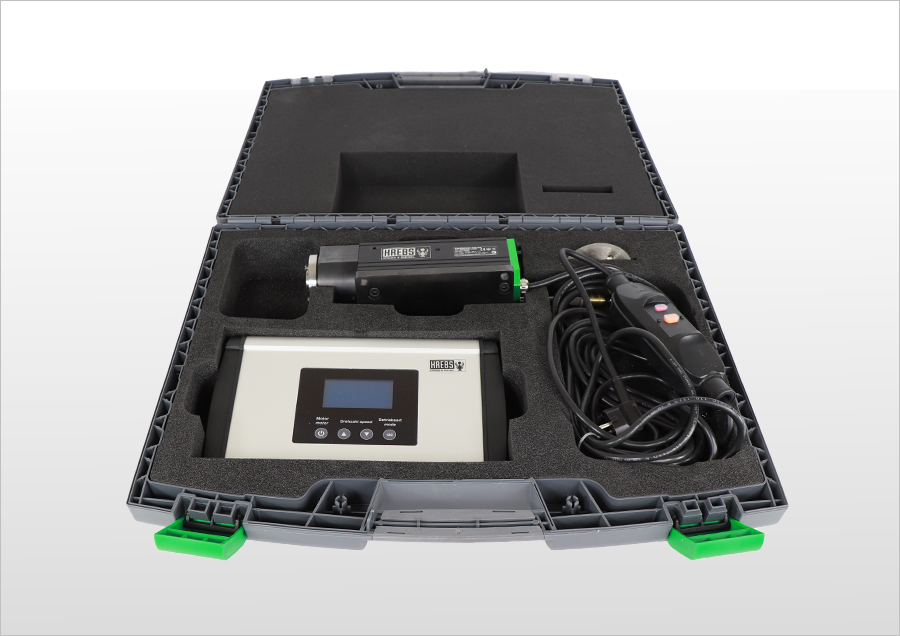

Mobile Dressing Spindle Control Unit - The Modern Control Center

The control unit of the mobile dressing spindle is equipped with a sensitive touchscreen for easy operation.

Like the spindle, the control unit is ultra-compact: Its base is slightly smaller than an A4 sheet, and its

height is less than 6 cm. All technical data are listed in the table. The entire system is delivered in a case,

making it always available for use anytime, anywhere.

Mobile Dressing Spindle KREBSDRESS - The Dressing Tool for Common Dressing Applications

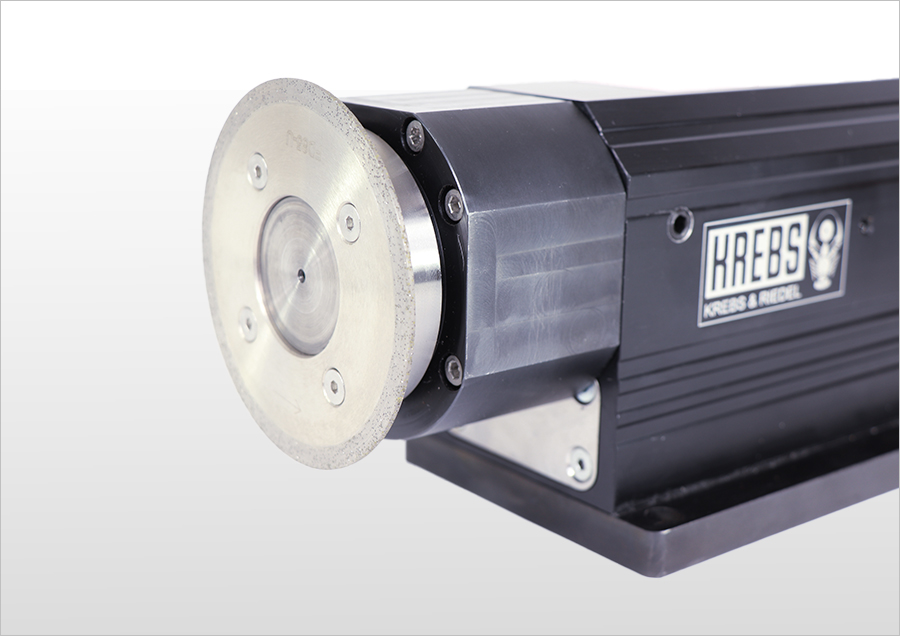

The mobile dressing spindle can be equipped with different dressing tools. The type FD85 dressing wheel is available for the most common dressing applications. For special applications, we also offer custom-made dressing tools. Contact us for more information!

TECHNICAL DATA

Technical Data: Mobile Dressing Spindle 300AS

Speed Range: 1,500 - 15,000 RPM

Voltage / Frequency: 230V / 50-60Hz

Current Consumption: approx. 1.7A

Power Output: approx. 300 watts

Torque: 20 Ncm

Spindle Connection Cable: Oil-resistant, 7 m with 7-pin plug

Sealing Air Connection: Ø 6 mm

Sealing Air Pressure: 1 - 2 bar

Protection Rating: IP 66 with connected sealing air

Protection Class: I

Right-/Left-hand Rotation: Yes

Bearings: Precision spindle bearings made in Germany

Spindle Dimensions: 261 x 100 x 115 mm

Spindle Weight: 6 kg

Technical Data: Control Terminal BT-01

Voltage / Frequency: 230 V AC / 50-60 Hz

Control Elements: Main switch, motor on/off, speed, operation mode

Display: 70 x 38 mm, blue backlit

Fuse in Control Panel: 10AT and 1AT, size 5 x 20 mm

Dimensions: 294 x 185 x 57 mm

Weight: 1 kg

Max. Ambient Temperature and Humidity: 40°C at max. 50% RH